How We Test LCD Enclosures

Posted by: Richard Williams | Posted on: | 0 Comments

Because of the varied environments LCD enclosures find themselves in, ensuring they can withstand the demands of the location is essential. Designing a product to cope with rain, excessive temperatures and physical impact is one thing, but it is impossible to ensure the LCD enclosure operates to design specifications unless it is thoroughly tested.

Testing an LCD enclosure means ensuring the housing can withstand the same environment of its intended use. This is not always easy as some customized LCD enclosures are designed to withstand some severe conditions, such as freezing locations where temperatures are well below zero, to hot climatic locations where temperatures reach 40 degrees centigrade.

Weatherproofing

Protecting an LCD screen against the weather means ensuring the LCD enclosure is waterproof. International and national rating systems such as IP65 and NEMA 4 provide guidance to the severity of rainfall and other elements an LCD enclosure can withstand; however, even building enclosure to these guidelines is no guarantee the product will adequately defend against the weather conditions of its intended location, so thorough testing is essential.

Saturation testing involves exposing the LCD enclosure to prolonged exposure to spray and cascading water. This is done with both a screen installed and without, enabling proper examination of the interior of the enclosure to ensure no water droplets have made their way inside the enclosure.

Temperature Testing

Because of the diverse range of conditions LCD enclosure operate in, from frozen locations close to the Arctic Circle, to hot, humid areas such as the sub-continent, making sure they can operate for prolonged periods at extreme temperatures is essential.

An environmental chamber provides the ability to test LCD enclosures in such extremes. Whether it’s an enclosure equipped to deal with sub-zero temperatures, with internal heaters and insulation, or an enclosure kitted out with additional cooling for hot locations, the environmental chamber enables simulation of these conditions, permitting prolonged testing and exposure for the LCD enclosures.

Physical Testing

As well as manufacturing LCD enclosures to the highest possible engineering specifications, from the highest quality mild steel, making sure the screen is kept safe requires the use of shatterproof screens.

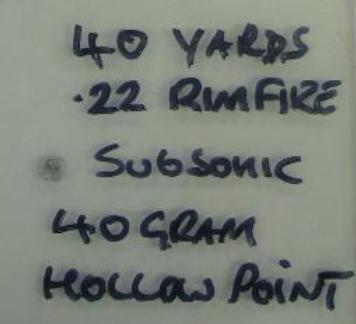

The shatterproof screens used in Armagard enclosures is tested by the manufacturers to withstand a subsonic hollow point bullet (.22 calibre) fired at 40 yards.

Post shortlink:

Popular Products

LCD Enclosure

Need armor for your LCD/LED screen(s)? Outdoors or inside the versatile LCD enclosure protects against thieves, vandals & the weather. Installation idea: NFL stadiums.

Outdoor Digital Signage

Exclusive 46” outdoor screen protection. Dubbed the ‘Totem’, due to its distinct design, it repels damage threats, but attracts audiences. Installation idea: Drive-thru restaurants.

Portrait Flat Panel Enclosure

Safeguard your eye-level advertising display screen(s), indoors or outdoors. Completely customizable, add exciting features like touch screen technology. Installation idea: Restaurant frontages.

Indoor Digital Signage

Popular purchase for retail outlets! Great for ‘point of sale’ persuasion, boost your brand with static & motion advertising from a single unit! Installation idea: Mall of America.